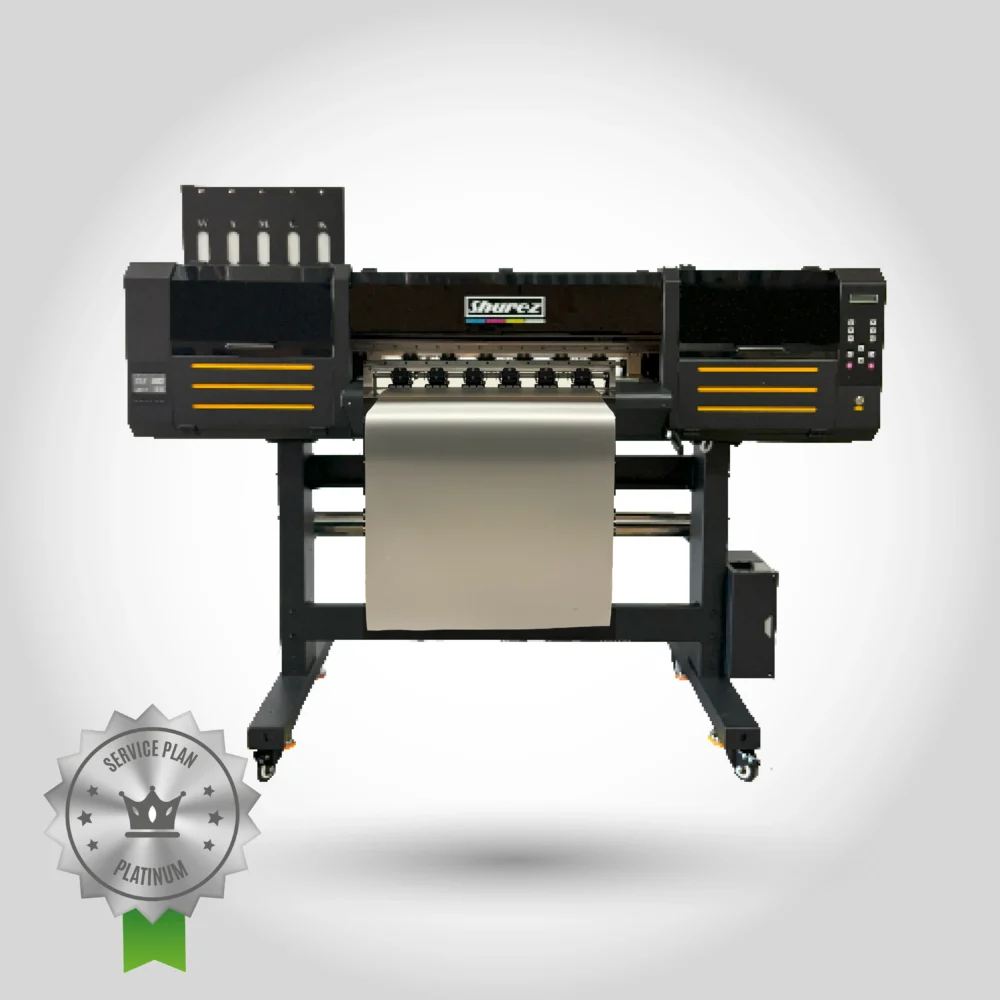

ESS recently introduced two new products, the UV Raccoon and the DTF System E024. Many customers ask, what is the difference between UV DTF printing and DTF printing? In this blog we tell you what those differences are:

1. Different production processes

DTF printing consists of first printing the designed pattern on the DTF film, then covering the pattern with hot melt powder and baking it to melt. Finally, transfer the pattern to various colors of pure cotton or cotton-poly blend using heat transfer cloth, cotton canvas, and other products. It is also the printing system par excellence for dark fabrics.

UV stands for ultraviolet rays. The drying principle of UV DTF printing is that the ultraviolet wave emitted by the LED cold light source lamp reacts with the photosensitive curing agent in the UV ink, causing the pigment molecules in the UV ink to solidify on the surface of the material, thus completing the printing action.

2. Different application industries

DTF printing is currently used in toys, gifts, clothing, advertising and other industries. Its advantage is that it can be printed on curved and irregular surfaces. And in turn, as we already mentioned, its main advantage is printing on dark fabrics.

UV DTF printing is mainly used in ceramic tile, glass, metal, leather and other industries, there is no limit. The advantage is that it is easy to operate. And you can mark an infinite number of surfaces!

At ESS we have a machine for every need of our customers.

In addition to personalized advice, we provide technical service and sell supplies.

Start your DTF printing business today.

Request your budget here: (LINK TO CONTACT FORM)