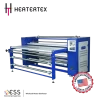

SERIE HS:

It is the most profitable option to enter the sublimation market.

• Steel cylinder with Teon surface to prevent rust and maintain uniform temperature.

• Eective, advanced and economical heating system.

• Industrial heating system with thermal oil.

• Cylinder rotation speed controller.

• Digital temperature controller.

• Option to change the rotation in the cylinder movement.

• Four tension rollers for the blanket.

• Work table for item-to-item applications.

• Oil level indicator to ensure the amount of oil in the cylinder.

• Automatic rollers to collect used material.

• Designed for continuous roll sublimation and item sublimation.

• Emergency stop device.

• Blanket protection alarm through limit sensors.

Technical Specifications

Belt width: 47” / 120 cm

Heat transfer principle: Thermal oil

Thermal cylinder diameter: 7” / 18 cm

Power required: 4 KW – 5 KW aprox.

Frequency: 50-60 Hz

Load rollers: 3

Take rollers: 3

Current: 17A-25A at AC 220 V

BROCHURE – Features and Specifications – Download

Productivity: 19” up to 59” per min / 0,5 up to 1.5mts per min

Transfer system: Roll to Roll and Piece to Piece

Startup time: 30 / 60 minutes aprox.

Dimensions: 50”x 74”x 51” / 127cm x 190cm x 130cm.

Working table: 55” x 23” / 140 cm x 60 cm

Weight: 1150Lb / 550Kg aprox.

Max temp: 50 – 70 min about. 3

Reviews

There are no reviews yet.