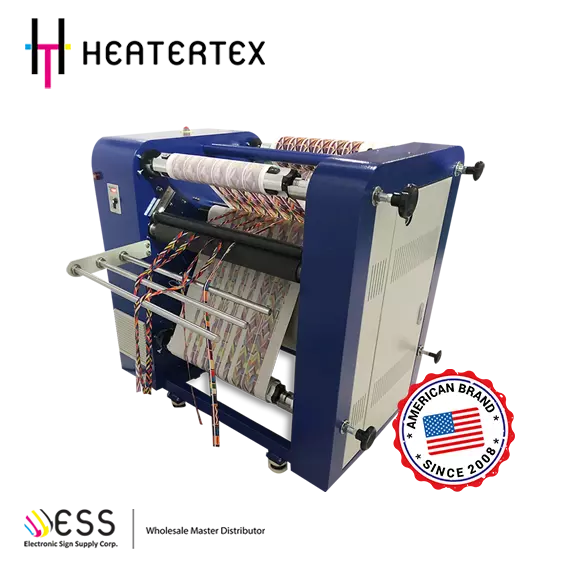

HT SERIES:

It is made to guarantee a continuous production in the sublimation line.

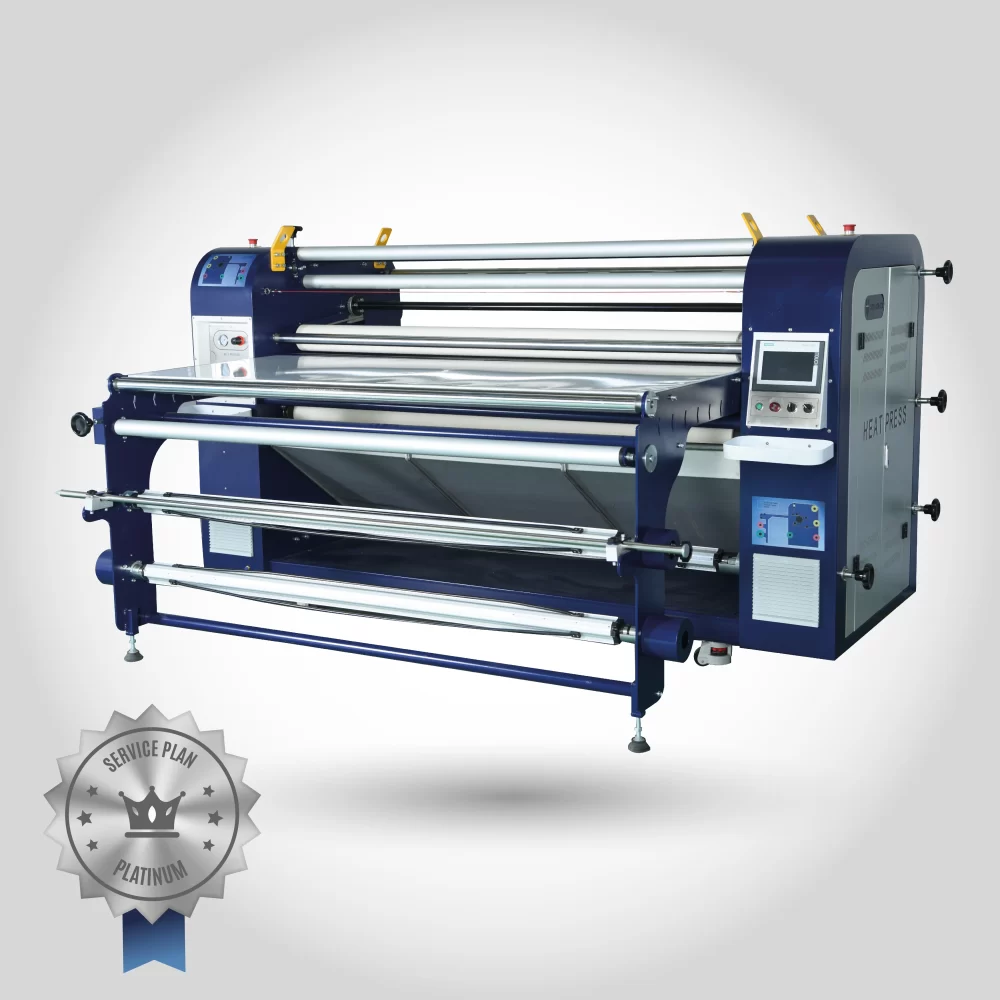

– Automation of daily work through the on and off programming system

– Efficient, advanced and economical heating system.

– Steel cylinder with Teflon surface to prevent oxidation and maintain uniform temperature.

– Industrial heating system with thermal oil.

– LCD touch screen

– Password to access special options on the LCD panel

– Sublimated fabric meter counter, configured from the LCD panel with the option toreset the value.

– Speed controller for cylinder rotation through the PLC.

– The Machine controlled by the SIEMENS brand PLC.

– Digital temperature controller can be programmed by the PLC.

– Automatic blanket position correction system controlled by the PLC.

– Pneumatic tension system for sublimation paper controlled by the PLC.

– Oil level indicator to ensure the amount of oil in the cylinder.

– Designed for continuous roll-to-roll and fabric sublimation.

– Independent control system on each roller to collect the used material.

– Option to change rotation in the movement of the cylinder

– Opción de cambio de giro en el movimiento del cilindro

– Blanket protection alarm through limit sensors.

– Emergency stop device.

– Pneumatic system for tension control on protective paper, fabric and printed paper.

Technical Specifications

Heating principle: Thermal oil.

Voltage: Three-phase 380 V AC / 220 V AC

Cylinder: Size: 190 cm / 75”| Diameter: 65 cm / 33”

Production: 1 to 5 mt/ min (39” to 159”/ min)1

Sublimation width: Approx. 185 cm / 72”

Air supply: 100 PSI

Working temperature: 210°C to 215°C / 410°F to 419°F

Load rollers: 3

Reels: 3

Warranty: Un year warranty

Heating time: 50 / 70 minutes approx

Power: 36 Kw

Transfer system: Roll to roll and piece by piece

Dimensions: 305cm x 270cm x 190cm / 120”x 106”x 75”

Applications: Dresses, skirts, kimonos, jackets, leggings, crop tops, flags, curtains, footwear, banners, parades, vests, bed covers.

BROCHURE – Features and Specifications – Download

Reviews

There are no reviews yet.